Little Demon Conical Fermenter

50 in stock

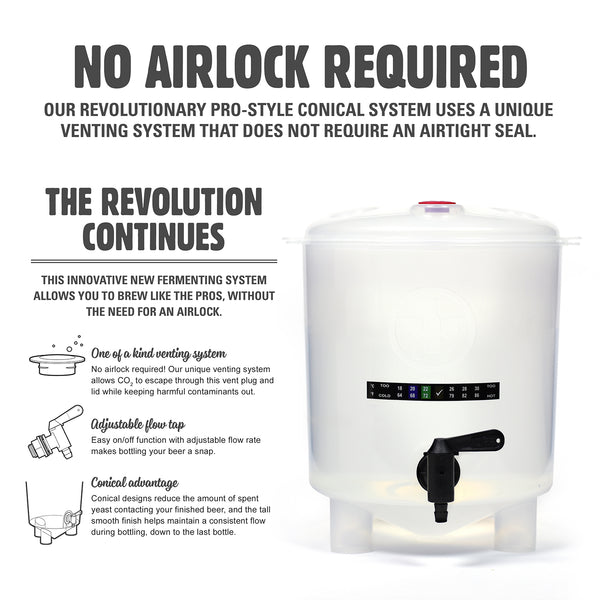

Brew like a pro with the "World's Smallest" Conical Fermenting System! This patent pending brewing system includes our 1 gallon Baby Conical, which is the perfect volume to brew a 1 gallon batch of beer, hard cider, wine and mead. This fermenter is made of a heat tolerant, food grade plastic (Phthalate and BPA free) that imparts no unwanted flavors into your brew. The conical design allows for easy transfer of your beer into bottles while that pesky trub (inactive yeast and other unwelcome items) stays securely at the bottom.

Includes

- 1 Gallon Conical Fermenter - Frost

- Adjustable Flow Tap Assembly

- Stick-on Temperature Strip

- Venting Plug (no airlock required)

Brewer's Note

Downloads

Testimonials

Love you guys, you're awesome! You make life easy for guys just learning how to make beer.

Mark

Source

I have never been a stout fan but this recipe really won me over. I plan to have this on hand all summer.

Russell

Looking forward to many more years of BREWDEMONS wonderful products and great service!! Enjoy some fun America!!

Scott

Truly a wonderful little set up. Much easier than the 5 gallon bucket, cook the mash approach, and the results are excellent!